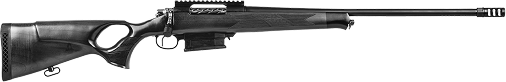

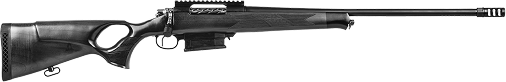

At the heart of our production philosophy lies the blending of the most advanced technology with human craftsmanship. Balıklı Silah Sanayi possesses a global-standard machine park and quality control processes to guarantee the perfection of every single part.